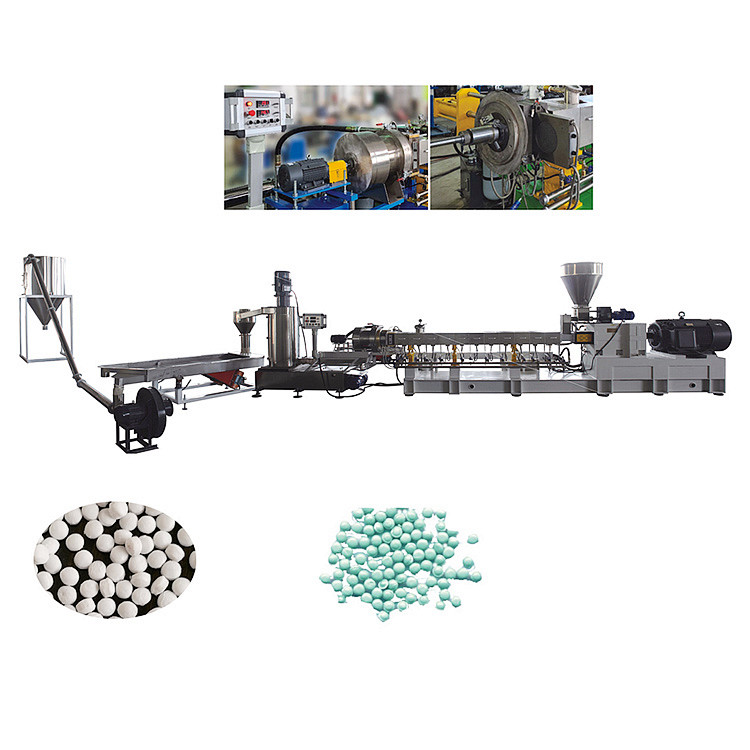

Water ring pelletizer machine

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

Detailed Product Description

Screw Design:Twin Screw ExtruderPlastic Type:PP/PE White Filler Masterbatch

Warranty:One YearScrew Diameter:71mm

Screw & Barrel Material:W6Mo5Cr4V2Cutting Type:Water Ring Hot Cutting

Capacity:2000kg/hColor:Any Color Can Be Customzied

White Filler Masterbatch Machine Twin Screw Extruder Plastic Pellets Machine

product advantages

Reduce production costs

Improve labor efficiency

Wide range of applications

High output, high quality

Detailed Product Description

Screw Design: | Twin Screw Extruder | Plastic Type: | PP/PE White Filler Masterbatch |

Warranty: | One Year | Screw Diameter: | 71mm |

Screw & Barrel Material: | W6Mo5Cr4V2 | Cutting Type: | Water Ring Hot Cutting |

Capacity: | 2000kg/h | Color: | Any Color Can Be Customzied |

White Filler Masterbatch Machine Twin Screw Extruder Plastic Pellets Machine

Water Ring Pelletizer Application:

1. PE, Eva etc + Caco3, talk, Tio92, filling modification and carbon black etc.

2. LDPE, HDPE, LLDPE,MDPE, drivepipe, insulation material, crosslinking material, cable coating material, thermal contraction pipe material etc.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic elastomer, EVA and hot melt adhesive etc.

4. PE, ABS, PS, EVA masterbatch etc.

5. ABS, EVA flaming retarding masterbatch etc.

6. PE, PP, PS filling and biodegradable masterbatch, etc.

Quick details

Screw diameter:71mm

Screw material:W6Mo5Cr4V2 high speed tool steel

Barrel diameter:72mm

Barrel material:W6Mo5Cr4V2 high speed tool steel

L/D:48/52:1

Output:2000-2500kg/h

Formula:PE/PP+80-85% caco3+PE wax+additives

Main technical data of various model of twin screw extruder pelletizing machine

Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | ||

SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Photo of SJSL75D filler masterbatch machine

ZHANGJIAGANG FUNGWAH MACHINERY CO.,LTD

The company was established in April 1995,is located in jiangsu zhangs' port,mainly engaged in plastic extrusion machine, washing recycling line, plastic crusher,pipe productionline, production line and other plastics research and development, production, sales andother business. Enterprise strength strong, strong technical force, strict grasp the production quality, at the same time uphold the operating principle of goodfaith. Operatedby reliable product quality, reasonable price, well received by customers, has many longterm partner. To use platform to make a man of insight for a better future.

Today the quality of tomorrow' s market. Start now!L ook to the future! With person whowith breadth of vision to create plastic industry tomorrow.

product advantages

product advantages

1. Wear and tear

Due to the convenient opening, the degree of wear of the threaded elements and the inner sleeve of the barrel can be found at any time, so that effective maintenance or replacement can be carried out. It will not be discovered when there is a problem with the extruded product, causing unnecessary waste.

2. Reduce production costs

When manufacturing masterbatch, it is often necessary to change the color. If it is necessary to change the product, open the open processing area within a few minutes. In addition, the mixing process can be analyzed by observing the melt profile on the entire screw. At present, the common twin-screw extruder needs a large amount of cleaning material to clean the machine when changing the color, which is time-consuming, energy-consuming, and waste of raw materials. The split twin-screw extruder can solve this problem. When changing the color, it only takes a few minutes to quickly open the barrel for manual cleaning, so that no or less cleaning materials can be used, which saves costs.

3. Improve labor efficiency

During equipment maintenance, the heating and cooling system of the ordinary twin-screw extruder is often removed first, and then the screw is drawn out as a whole. The split twin screw is not needed. Just loosen a few bolts and turn the worm gear box handle device to lift the upper part of the barrel to open the entire barrel and then perform maintenance. This not only shortens the maintenance time, but also reduces the labor intensity.

4. Wide range of applications

Wide range of applications, suitable for processing a variety of materials

5. High output, high quality

It has other advantages of ordinary twin-screw extruder, and can realize high output, high quality and high efficiency.