Pvc Pelletizing Machine

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

The main working mode of the PVC granulator is agglomerate wet granulation. A certain amount of water or steam is used to make the basic fertilizer fully chemically react in the cylinder after the humidity is adjusted. Under a certain liquid phase condition, with the help of the rotating movement of the cylinder, Make the material particles produce squeezing force to reunite into balls.

The main advantage lies in the use of steam to heat the humidity, increase the temperature of the granulated material itself, reduce the granulation moisture, reduce the load of the dryer, and improve the work efficiency.

Product Description

PVC plastic pelletizing machine / recycle plastic granule making machine

pvc plastic pelletizing machine configuration reference

This pelletizing machine is composed by SJSZ series conical twin-screw extruder and correspondingly pelletizing auxiliary equipment; It is suitable for pelletizing PVC material. The pellets produced by this line are even, solid, elegance.

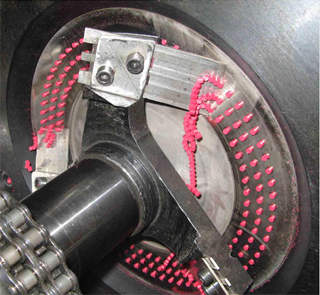

The pelletizing auxiliary equipment includes die face cutter, air transferring unit, vibration separating and cooling unit,with features of high automation and high production efficiency.

Extruder Model | SJSZ-51 | SJSZ-55 | SJSZ-65 | SJSZ-80 | SJSZ-92 |

Screw Dia.(mm) | Φ51/105 | Φ55/110 | Φ65/132 | Φ80/156 | Φ92/188 |

Main Motor(kw) | 18.5 | 22 | 37 | 55 | 90 |

Cutting motor(kw) | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 |

Granules size(mm) | 3 | 3 | 3 | 3 | 3 |

Output(kg/h) | 80~100 | 100~150 | 150~250 | 250~380 | 380~700 |

Screw Loader

Charging capacity: 300kg/h |  |

| Conical Double-Screw Extruder

Screw Diameter: Φ65/132mm |

Mould

Material: 38CrMoAl |  |

| Air bower and Hopper

Blower power: 2.2KW |