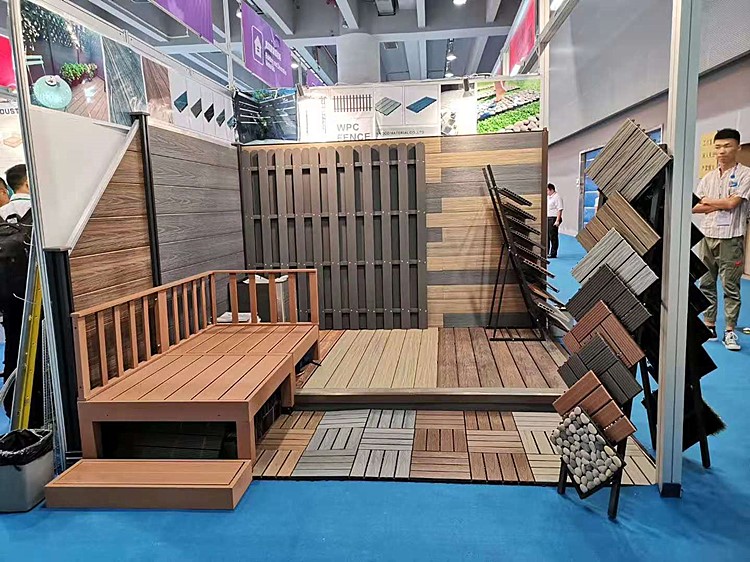

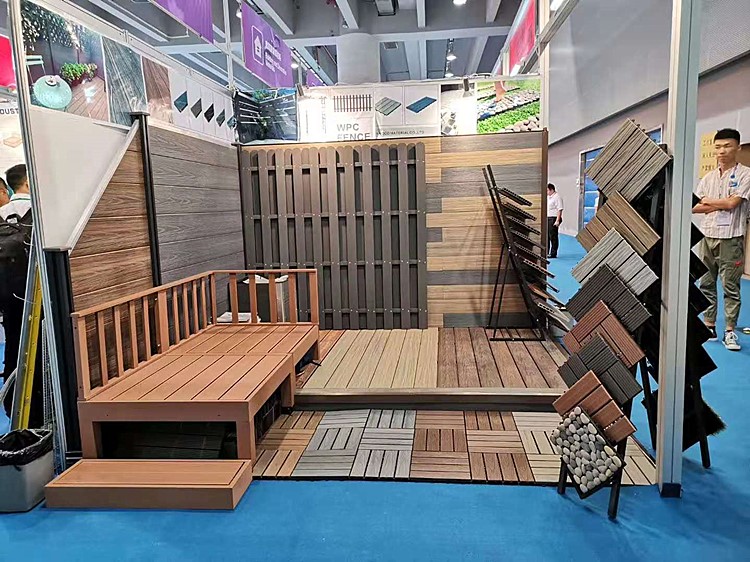

Wood Plastic Composite Decorative Wpc Pvc Ceiling Wall Panel Making Machine

Wood Plastic Composite Decorative Wpc Pvc Ceiling Wall Panel Making Machine

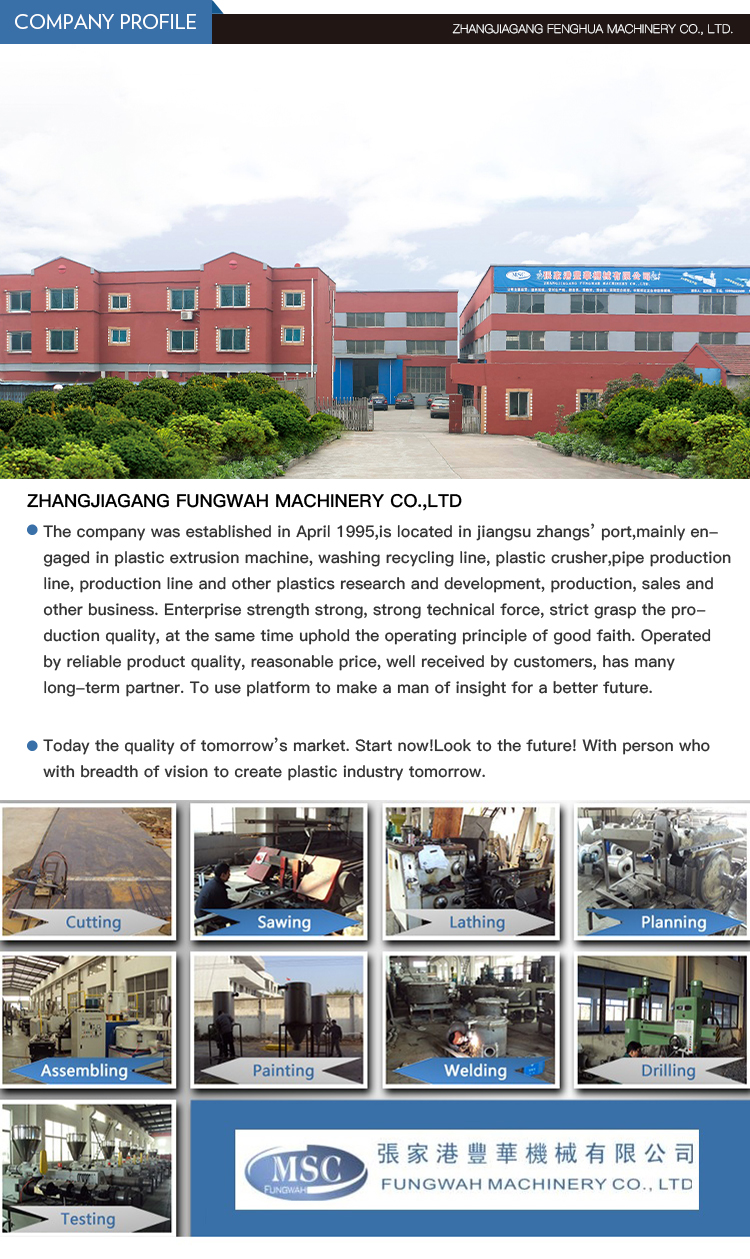

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

Packaging Details

WPC Board Making Machine WPC Plastic Floor Wall Panel Machine Plant:

1. Mould package:Plywood package;

2. Outside package:Stretch film;

3. Loading container: 1X40GP.

Wood Plastic Composite Decorative Wpc Pvc Ceiling

You just tell me the dimension of the WPC product you want to produce, let us do the rest work:

1. Design and manufacture suitble machine for you.

2. Before delivery, we will test the machine until you are completely satisfied.

(You can come to our factory to inspect the running production line.)

(2) Field installation and commissioning;

3. After-sales service:

(1) Free Spare Parts;(2) Field installation and commissioning;

(3) Field training your workers;

(4) Field maintenance and repair service ;

(5) Video/Online technical support.

(4) Field maintenance and repair service ;

(5) Video/Online technical support.

4. Turnkey project service:

(1) Complete production line;

(2) Drawing for factory layout and other information for helping customer to build the factory;

(3) Electric cabinet, water pump, air compressor, etc. that will be used in the new factory;

(4) Raw material;

(5) After warranty service.

(2) Drawing for factory layout and other information for helping customer to build the factory;

(3) Electric cabinet, water pump, air compressor, etc. that will be used in the new factory;

(4) Raw material;

(5) After warranty service.

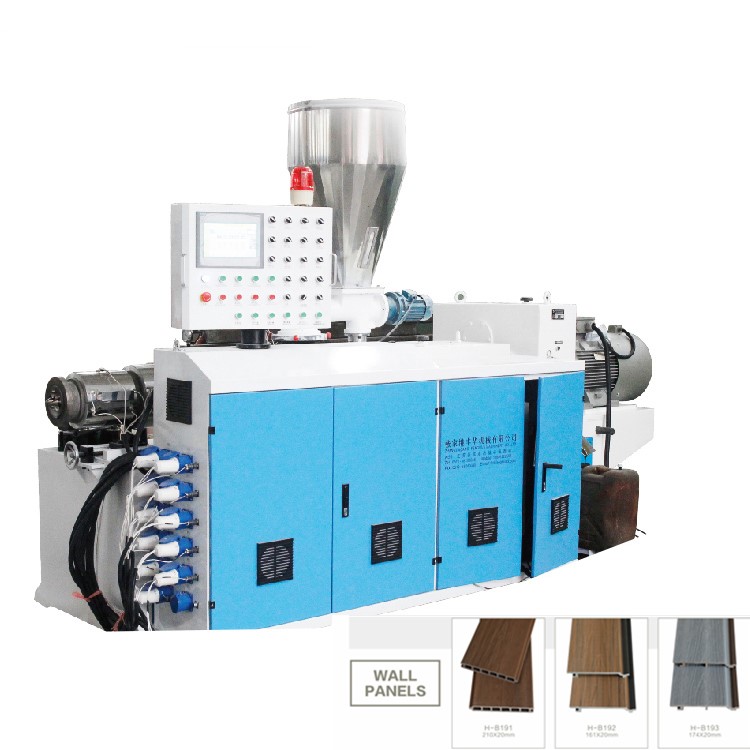

Model of high speed PVC wall panel production line:

| Model | 48/113 common | 53/128 common | 53/128 high speed | 65/132 high speed |

| Applicable product width | 200-250mm | 200-250mm | 200-300mm | 20-600mm |

| Extruder model | SJSZ48/113 | SJSZ53/128 | SJSZ53/128 | SJSZ65/132 |

| Capacity(kg/h) | about 2200(about 800 square meter/24h) | about 3000(about 1200 square meter/24h) | about 4000(about 1600 square meter/24h) | about 8000(about 3300 square meter/24h) |

| Main motor power(kw) | 15 | 22 | 22 | 37 |

1. Conical twin screw extruder (with automatic feeding machine)

(1) Motor: Siemens brand

(2) Inverter: ABB brand

(3) Contactor: Siemens brand

(4) Temperature controller: Omron brand

(3) Contactor: Siemens brand

(4) Temperature controller: Omron brand

(5) PLC: Siemens brand

(6) Heating method: Cast aluminum heating

(7) Material of screw and barrel: 38CrMoAlA.

(7) Material of screw and barrel: 38CrMoAlA.

2. Mould

(1) Extrusion mould material: 40Cr.

(2) Calibration mould material: Wearable tin bronze ZQSn5-2-5.

(3) Size: Customized

3. Calibrating and water cooling table

(1) Vacuum pump power: 3/4/5.5 kw

(2) Water pump power: 3/4/5.5kw

(3) Dimension(L*W*H): 6000*1000*1100mm

(3) Dimension(L*W*H): 6000*1000*1100mm

4. Haul-off machine and cutting machine

(1) Haul-off method: By caterpillars tracks.

(2) Haul-off speed: 1-10 m/min.

(3) Adopt ABB inverter.

(4) Pressing method: Pneumatic pressing.

(5) Effective clamping length:1200-2800mm.

(6) Cutting method: Chipless cutting

(7) Cutting knife raw material: Alloy steel

5. Bracket

It is used to hold products and can unload them automatically.

(1) Length: 6m

(2) Material: Stainless steel (3) Unloading method: Pneumatic unloading

Product Details