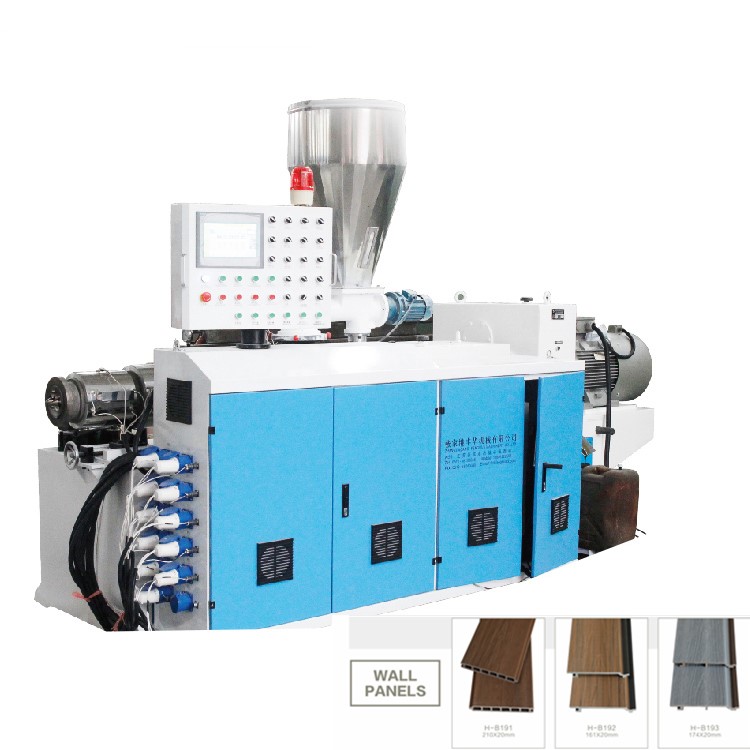

PVC Wood Plastic Cabinet Panel Production Machine

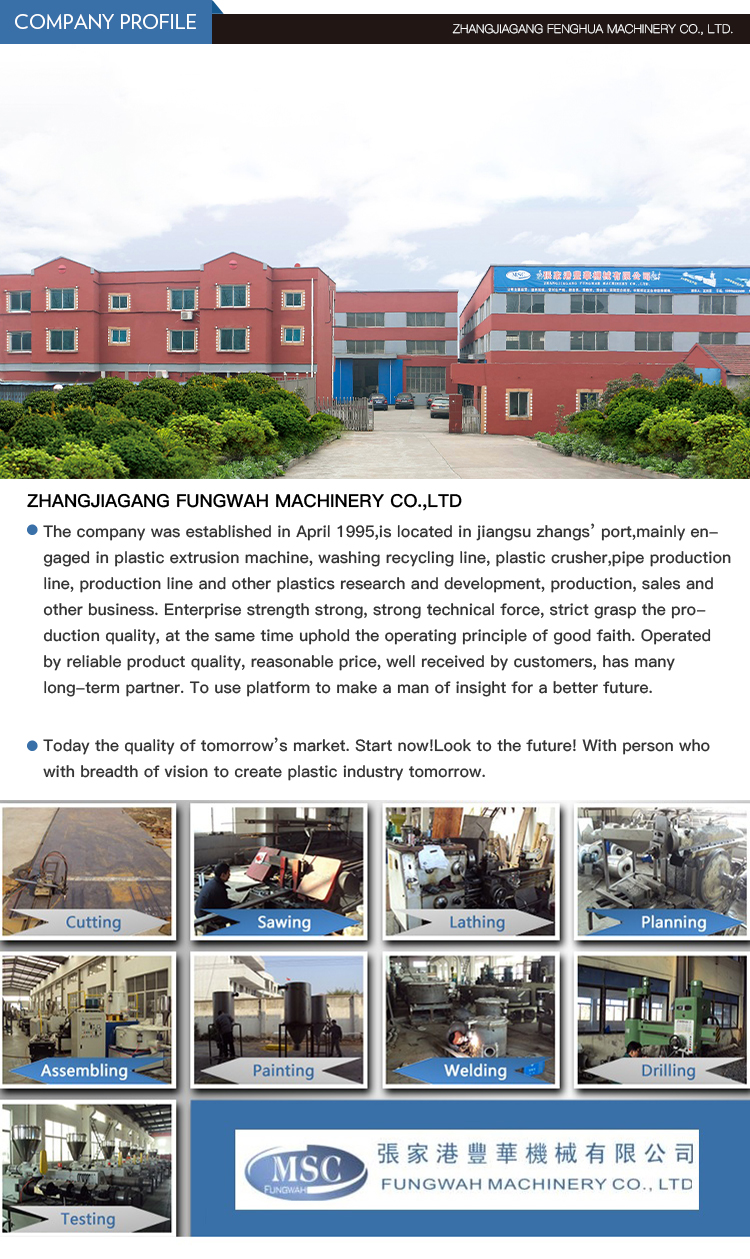

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

Main motor power:75kw

Motor brand:Siemens

Output capacity:300-400kg/h

Calibrating table:6000mm

Electrical component:ABB, Omron, RKC, Shneider etc.

PVC Wood Plastic Cabinet Panel Production Machine

Material:

pvc powder + wood powder/rice husks + chemicals

Production Process

Milling -- Mixing -- Granulating -- Extruding -- Mold -- Product -- Calibrating -- Hauling off -- Cutting -- Embossing or Polishing -- Final products

Main machines:

Milling machine,mixing machine,extruder,mould, vacuum shaping platform, hauling machine,cutting machine,material reversing platform,etc.

Machine Features:

1. This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber, and the material is of 90% of waste plastic and waste natural fiber

2. This production line can produce wpc products of different specifications only via changing mould.

3. PVC WPC door board production line is adopted specially designed HGMS80/156, HGMS92/188 conical twin screw extruder. The parallel twin screw extruder is used to mix the wood and plastic and get good homogeneous melt.

4. It adopts imported ABB and Siemens speed frequency converter.

5. It chooses imported RKC and Omron temperature controller.

6. This is one step WPC extrusion technology, which saves energy

7. The production line consist of conical twin screw extruder, moulds for door boards, forming moulds, calibrating cooling stage, caterpillar haul-off, transverse cutter and tilt stacker.

| Model | 48/113 common | 53/128 common | 53/128 high speed | 65/132 high speed |

| Applicable product width | 200-250mm | 200-250mm | 200-300mm | 20-600mm |

| Extruder model | SJSZ48/113 | SJSZ53/128 | SJSZ53/128 | SJSZ65/132 |

| Capacity(kg/h) | about 2200(about 800 square meter/24h) | about 3000(about 1200 square meter/24h) | about 4000(about 1600 square meter/24h) | about 8000(about 3300 square meter/24h) |

| Main motor power(kw) | 15 | 22 | 22 | 37 |