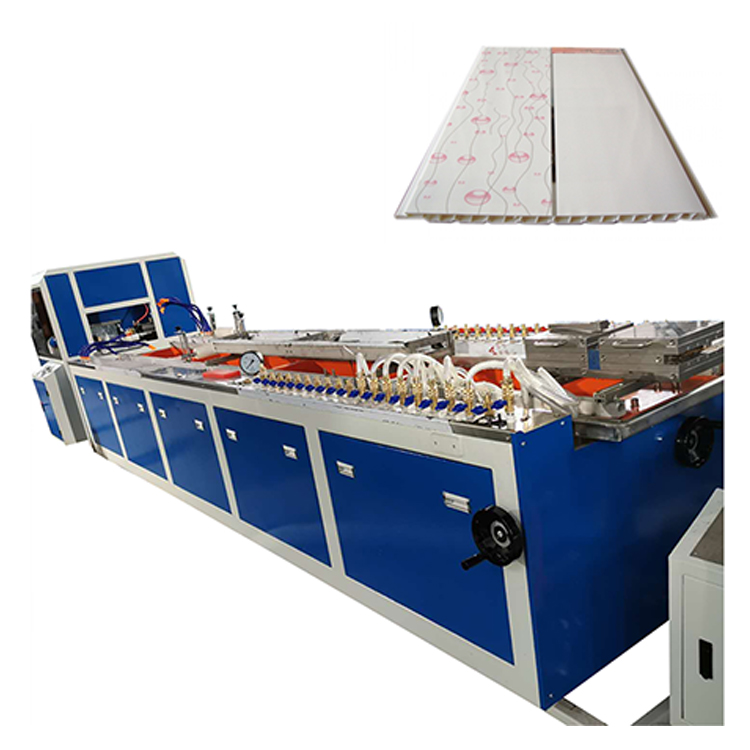

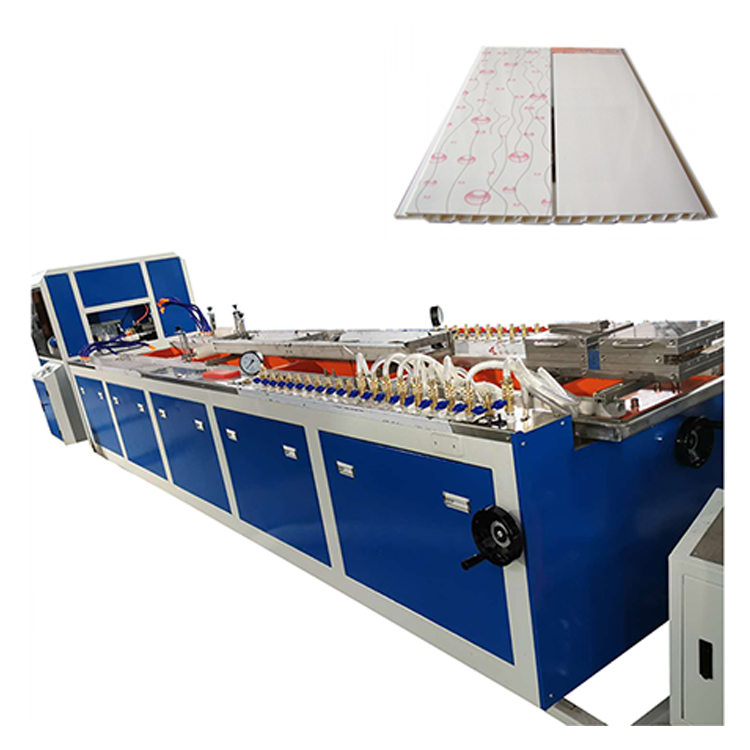

Pvc Ceiling Panel Production Line/machine /extrusion Machine

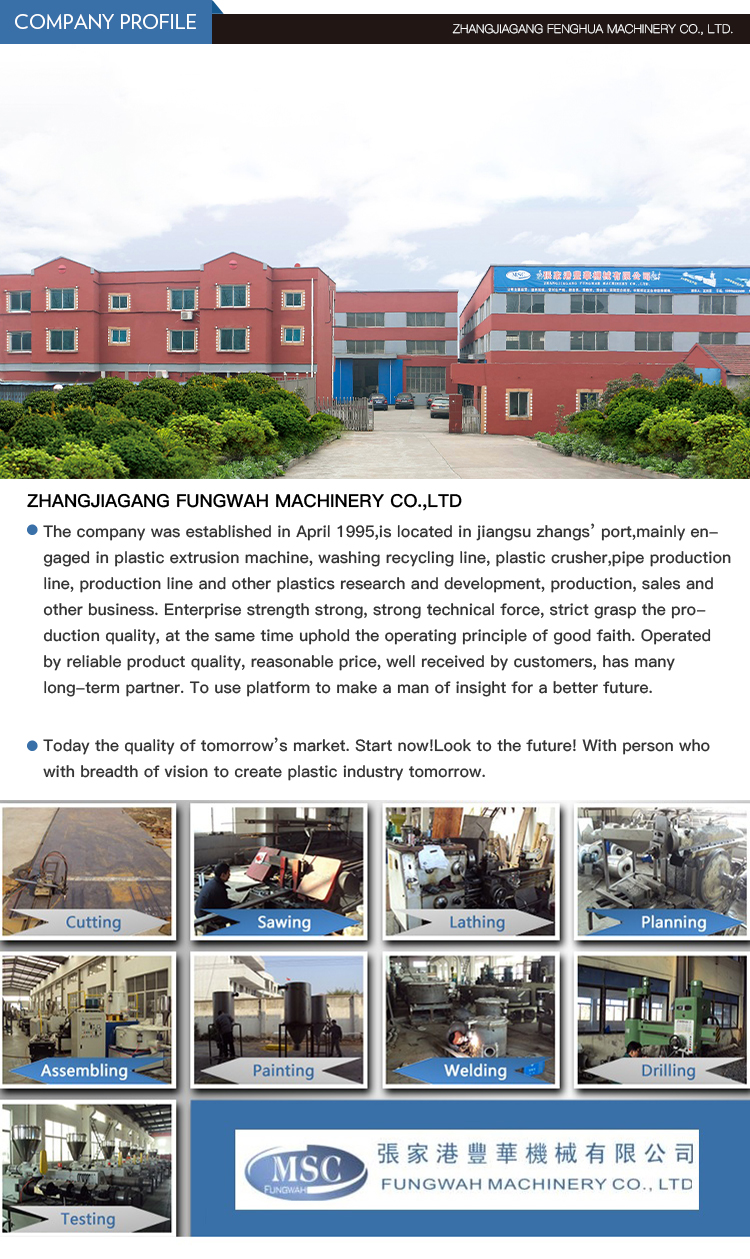

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

1. Even plastication and agglomeration,

2. Reliable quality,

3. Long servicing life and direct conversion of powder into plastic products.

4. Equipped with our company's different mould tools down stream equipment, they can directly produce plastic products like pipes, rods, plates and profiles.

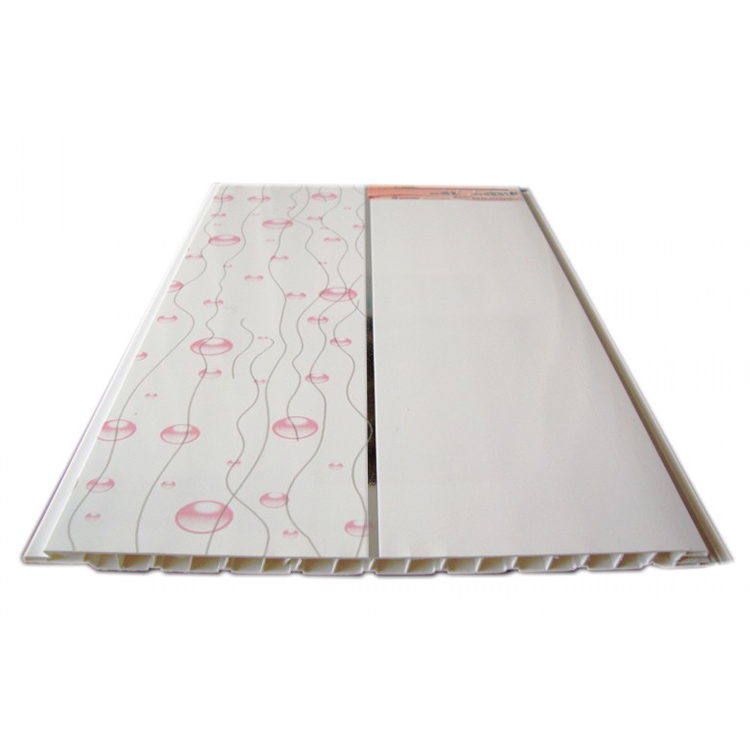

Pvc Ceiling Panel Production Line extrusion Machine

Features and application:

Features

1. Even plastication and agglomeration,

2. Reliable quality,

3. Long servicing life and direct conversion of powder into plastic products.

4. Equipped with our company's different mould tools down stream equipment, they can directly produce plastic products like pipes, rods, plates and profiles.

Application:

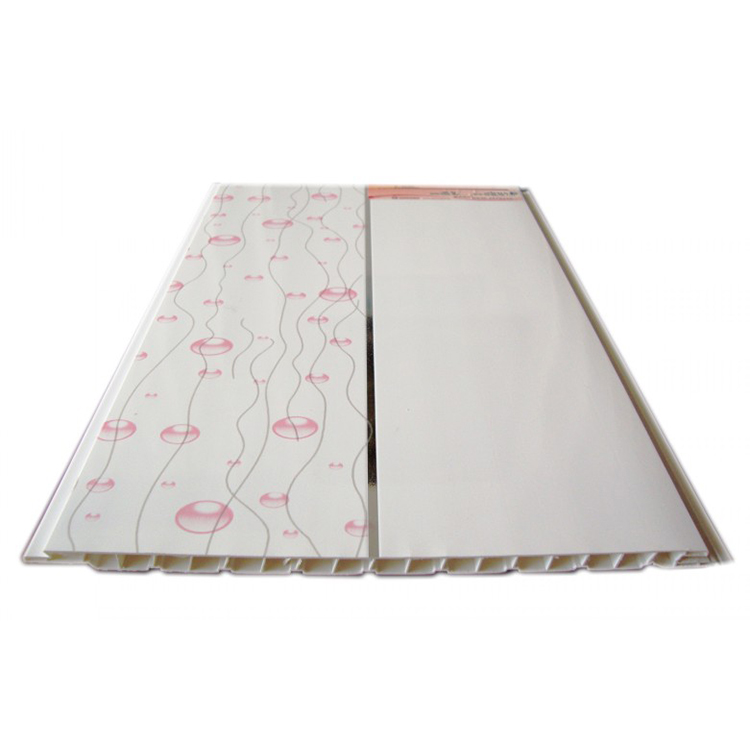

Advertisement: such as screen printing, computer lettering, ad board.

Architeture: such as buliding wall board, decoration board, housing, office, public buliding interlayer, commercial decoration shelf, non-dust room board, ceiling plate.

Transportation: such as steamship, aeroplane, carriage, traine compartment, roof shed, case core layer, inner upholster.

Industry: such as chemical industry antisepticizing project, thermoforming , for refrigeratory, for temperature keeping, for environment protection

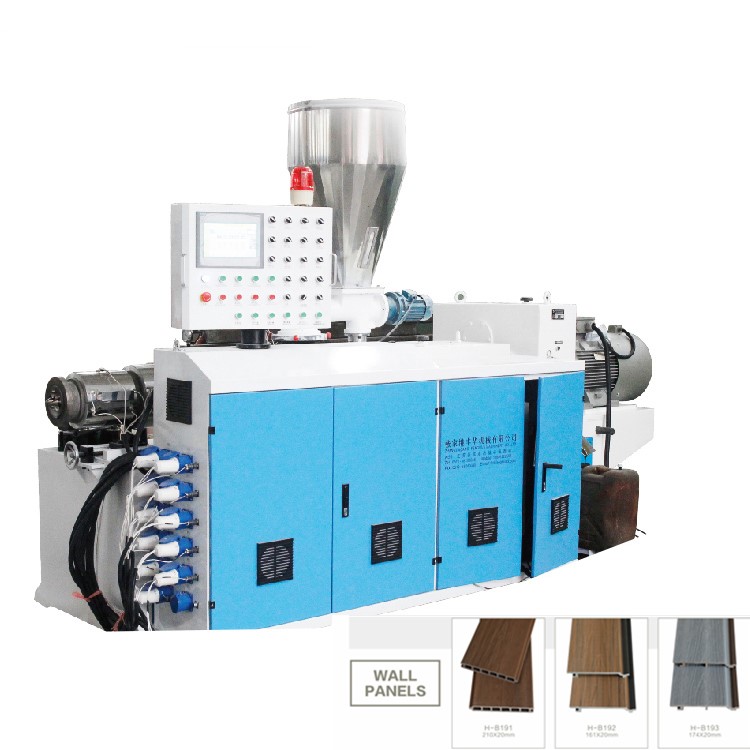

Model | YF180 | YF240 | YF300 | YF400 | YF500 | YF600 |

Max. width of product(mm) | 180 | 240 | 300 | 400 | 500 | 600 |

Extruder model | SJSZ55/110 | SJSZ65/132 | SJSZ65/132 | SJSZ65/132 | SJSZ80/156 | SJZ80/156 |

Max. extrusion capacity(kg/h) | 150 | 250 | 250 | 250 | 360 | 360 |

Extruder power(kw) | 22 | 30/37 | 30/37 | 30/37 | 55 | 55 |

Cooling water(M3/h) | 5 | 7 | 7 | 8 | 10 | 12 |

Compressed air(M3/min) | 0.2 | 0.3 | 0.3 | 0.3 | 0.4 | 0.5 |

Product Details