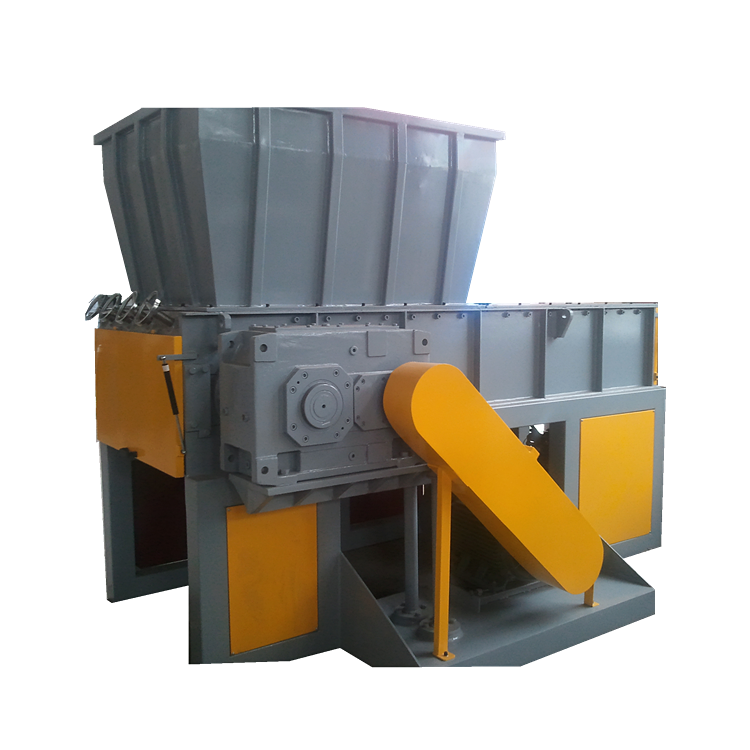

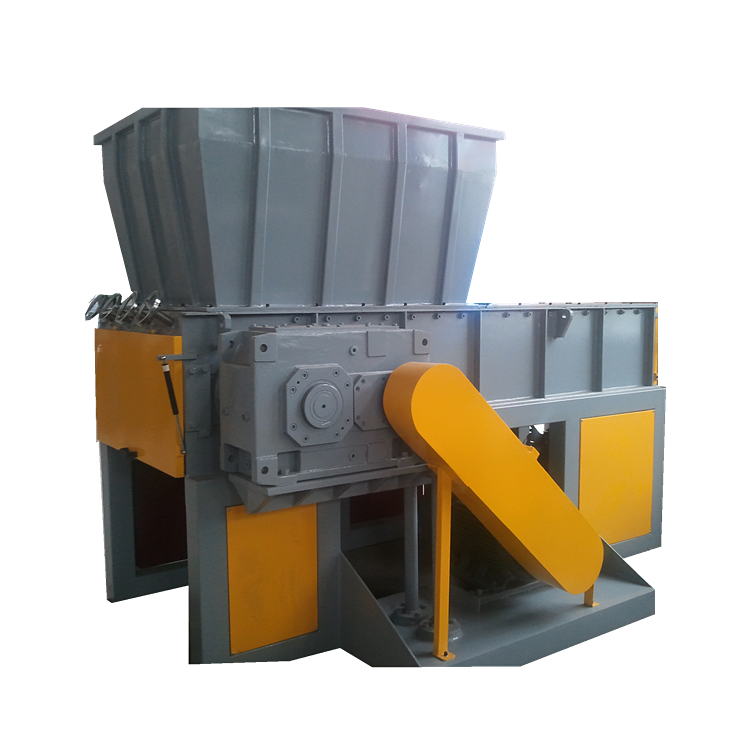

Pineapple Blade Shredder

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

Pineapple Blade Shredder Applications:

- Plastic lump and plastic block, like PP, PE, PET, PC, ABS, Nylon.

- Plastic pipes

- Film,Woven bags

- Living garbage,

- Medical waste

- Electronic Waste

- Copper Cable,Aluminum Cable with steel

- Aluminum cans

- Wood: Pallet,tree root,solid wood etc

Pineapple Blade Shredder

The Pineapple Blade shredders have been designed for the most demanding and high throughput applications in recycling industries,Clients could select the corresponding models according to the material size and quantity. Well as for the different special needs, providing a special knife rotor, for shredded material as film, woven bags or nylon, ABS and PC.

Applications:

- plastic lump and plastic block, like PP, PE, PET, PC, ABS, Nylon.

- Plastic pipes

- Film,Woven bags

- Living garbage,

- Medical waste

- Electronic Waste

- Copper Cable,Aluminum Cable with steel

- Aluminum cans

- Wood: Pallet,tree root,solid wood etc

Fetures:

• Teeth are DC53 steel. Stator knives are D2 steel.

• The main electronic controls are a combination of Siemens and Schneider.

• Microcomputer technology incorporating rotator speed variations with start, stop and reverse features.

• Automatic reverse sensors to protect the machine against over loading and jamming.

• Engineered using split bearing block technology so the blades can be changed quickly and efficiently.

• Specifically designed rotor to be extremely wear resistant.

• Rotor teeth can be rotated 4 times before they need changing, lowering running costs and reducing down time.

• Extremely versatile machine able to process a number of different materials

• Machinery protection, accord with the European CE standard.

Note: Through the moving and fixed knife cutting the material broken into small pieces, in under the action of water spray and broken friction makes preliminary finish cleaning materials .

Crushing warehouse: Using high hardness steel template, after processing, fine grinding, and assembled. With large thickness, high strength, high resistance to wear, no pollution, long life and other characteristics. Assemble the crushing warehouse disassembling and maintenance is very convenient .

The cutting tool : Use "V" type of cutting technology, the moving knife cut material evenly, to reduce the energy consumption, reduce noise, loading and unloading of the blade is very convenient. Using W18Cr4V material, has the characteristics such as high strength, good toughness, not easy fracture, and can guarantee good blade in the work, dismantling, repair and maintenance is very convenient .

A shaft : The use of special material processing and become, by the dynamic and static balance, has good toughness, work is not easy to deformation and stable working status, etc.

Belt wheel : All the machines on the belt wheel through the coupling form link transmission shaft and belt wheel, with balanced operation, precise, convenient tear open outfit, easy maintenance, etc .

Screen mesh : Mill sheet material is derived from the high strength steel. Sieve plate with high intensity, long service life. Machine sieve plate type of installation is very simple, easy to change, and have many different mesh screen for customers to choose.