PET Plastic Crushing And Washing Systems With 300kg/h

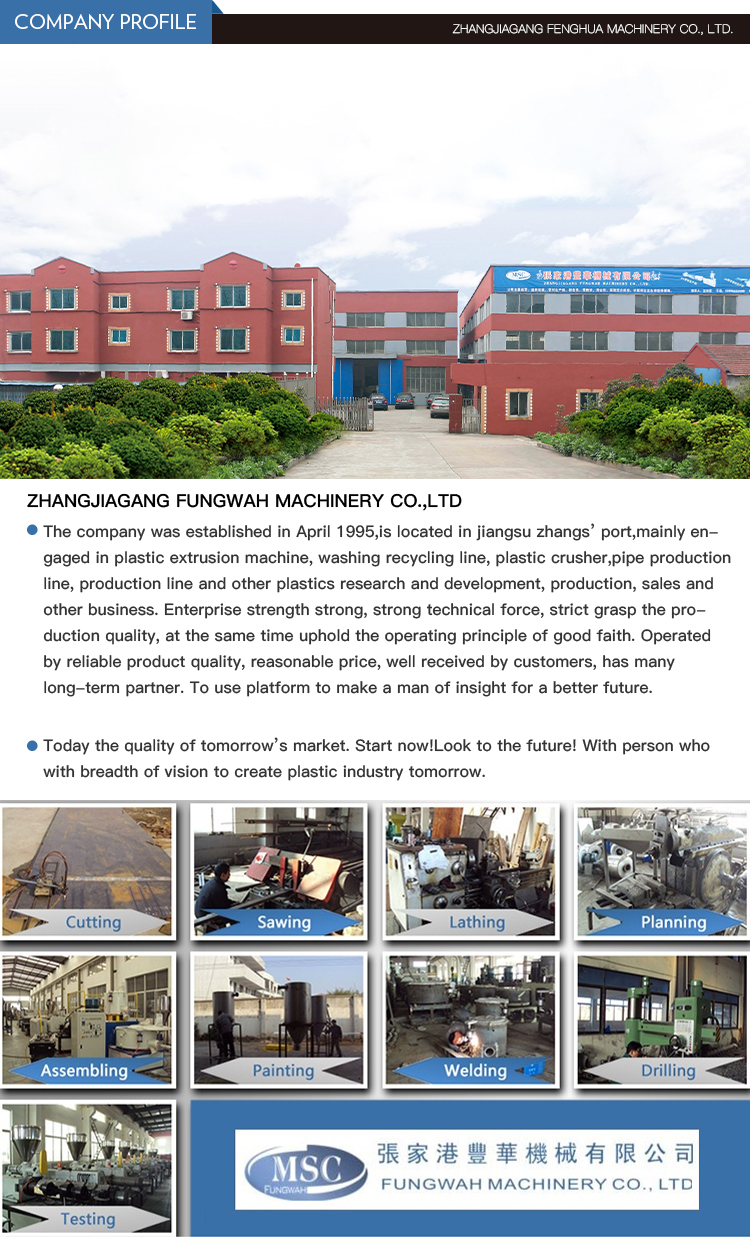

- FUNGWAH

- Jiangsu,China

- 45 Days

- 10 Sets/Month

PET Plastic Crushing And Washing Systems With 300kg/h

Pre-sale: we given client the details technician offer, sign the sales contract etc.

• In-sales: we supply the details layout, installation instruction, technician support for the clients.

• After sales: we arrange engineer to install the machinery and training the workers for client.

• We have 24hours team to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

PET Plastic Crushing And Washing Systems With 300kg/h

1 - Plastic recycling washing machine is applied in PET waste bottle or sheet recycling field.

2 - Through crushing, washing and dry process, the waste bottle or sheet will become to be bottle flakes. The flakes are widely used in plastic industry, like sheet, and profile production.

3 - The clean flakes can be used to produce the polyester staple fiber, strap band, granules, transparent film and sheets, etc. The top class flakes can be used to blow bottles again.

4 - Recycling machine can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products are very clean.

5 - Recycling machine output we can supply is from 300kg/h to 6000kg/h.

| Technical parameter of waste PP,PE film wahing line | ||||

| Output (Kg/h) | 200 | 300 | 500 | 1000 |

| Workshop area (L*W*H)(m) | 24*5*4.5 | 28*5*4.5 | 32*7*6 | 36*7*6 |

| Labors | 3-4 | 5-6 | 7-8 | 10-12 |

| Installation power (Kw) | 90 | 125 | 150 | 210 |

| Length of line | 24 | 26 | 26 | 35 |

• For the loose cargo we will packing by wooden box

• For the full container loading we are packing the machine by film and some on pallet accordingly

• We can shipping the goods by air or by sea

• We will send pictures of cargo loading to our client to check and keep recording

• We can send cargo to client’s warehouse to loading