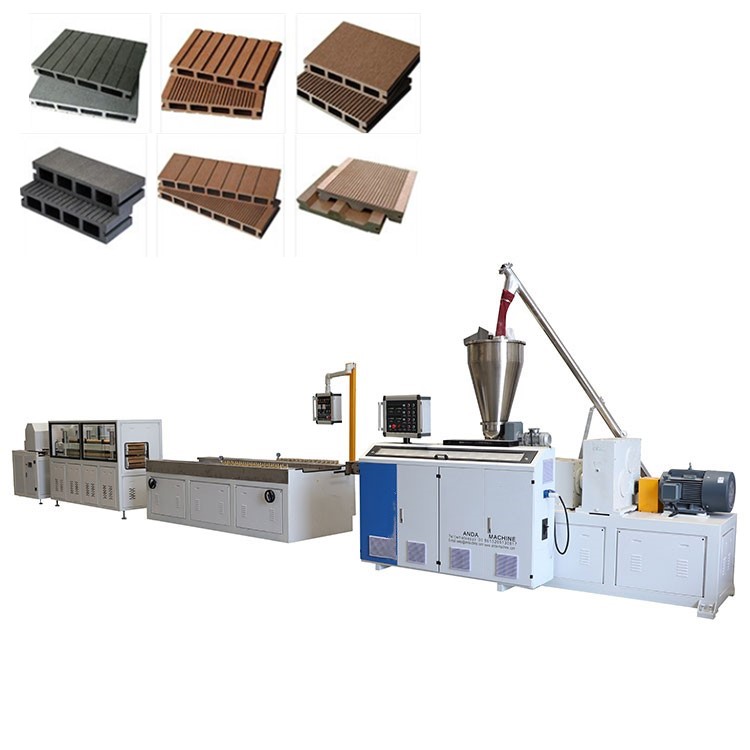

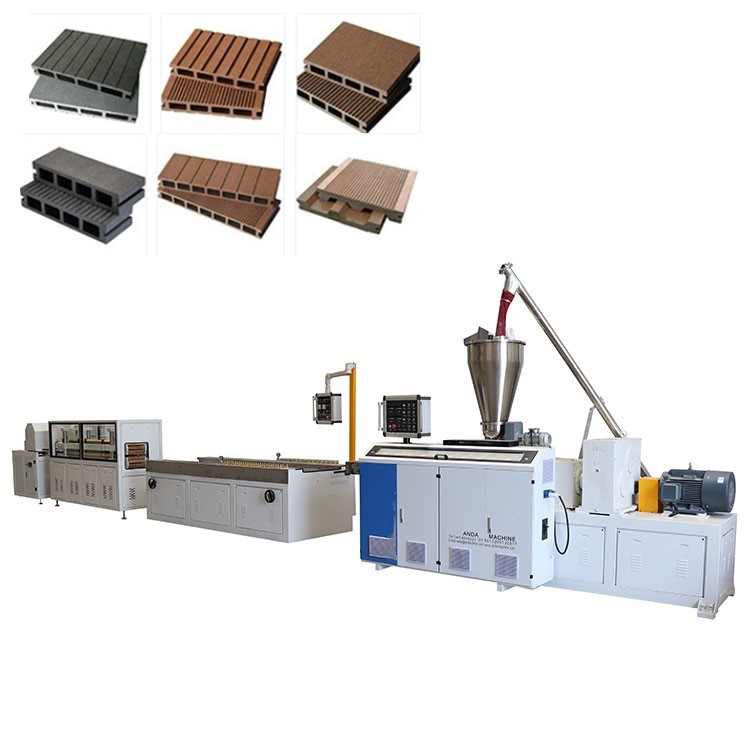

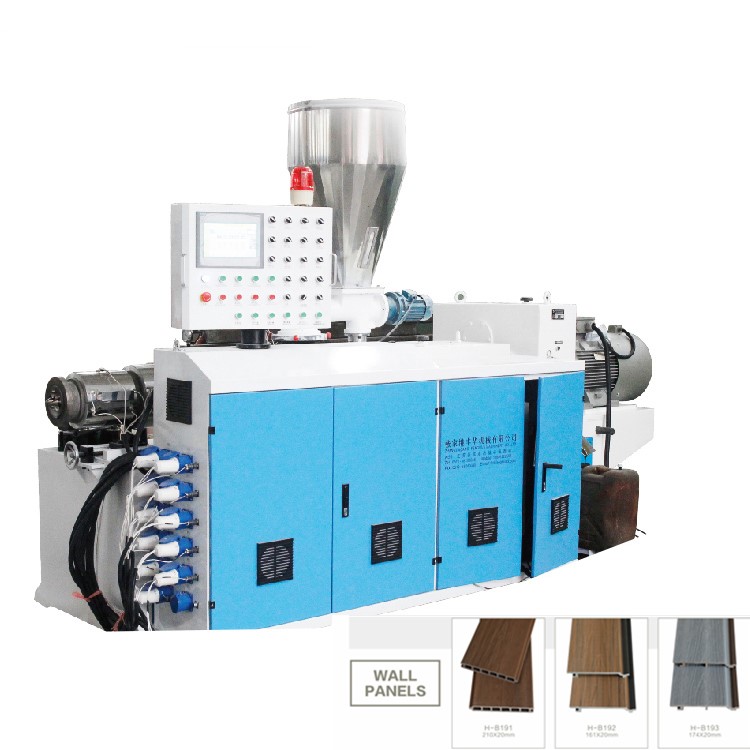

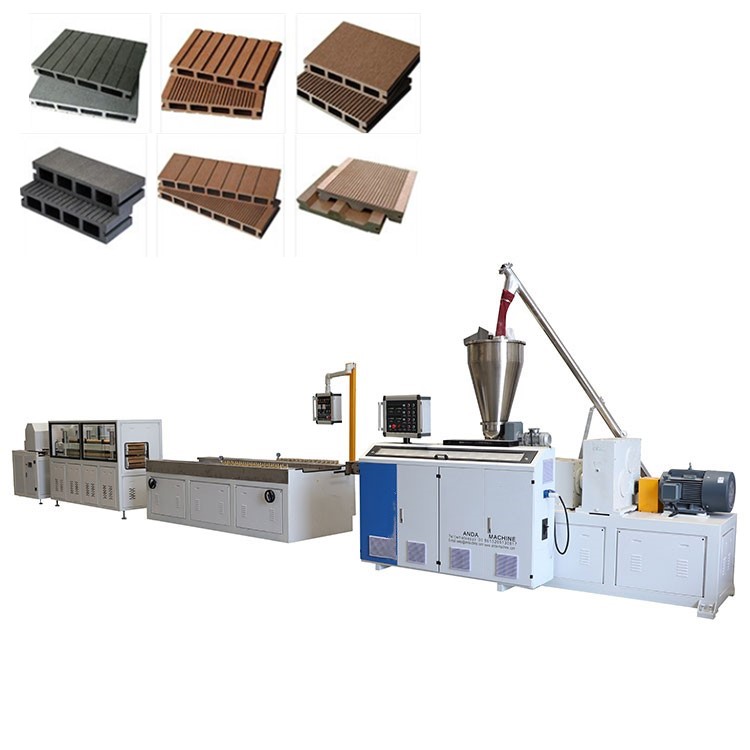

New Design WPC Hollow Panel Extrusion Line

Products features:

1. It can be used either and outer door board, partition, window sill etc. or PVC and PVC +wood extruding foaming craft.

2. The final products produced by the PVC door board extrusion line centralizes the characters of plastic and wood.

3. It not only has the special apperance effect, but also overcome the shortage of wood. It has good processability as wood, and the proportion can be controlled in 0.6-0.9kg/m.

4. It can be sawed, drilled, and planed by the wood working tools.

5. The WPC material and products have features of heavy acid bases resistance, water-proofing, corrosion, anti-moth, anti-aging, static-free and flame retarded

Model of WPC Hollow Panel Extrusion Line:

| Model | 48/113 common | 53/128 common | 53/128 high speed | 65/132 high speed |

| Applicable product width | 200-250mm | 200-250mm | 200-300mm | 20-600mm |

Extruder model

| SJSZ48/113 | SJSZ53/128 | SJSZ53/128 | SJSZ65/132 |

| Capacity(kg/h) | about 2200(about 800 square meter/24h) | about 3000(about 1200 square meter/24h) | about 4000(about 1600 square meter/24h) | about 8000(about 3300 square meter/24h) |

| Main motor power(kw) | 15 | 22 | 22 | 37 |

The WPC Hollow Panel Extrusion Line includes the below parts:

1, mixing machine for WPC PVC door making machine: high speed heating and cooling mixing

2. Feeder and extruder for WPC PVC door making machine: conical double screw extruder with high capacity design for WPC production.

3, die and mold for WPC PVC door making machine: you can change the mold for making different size of door panels.

4, calibrating machine for WPC PVC door making machine: vacuum and water cooling for high capacity production

5, haul off machine for WPC PVC door making machine: high power haul off device is specially designed for WPC door production.

6, cutting machine for WPC PVC door making machine: the cutter should be designed with high quality saw.